Semiconductors are a vital component of almost every electronic item we rely on in a modern world: cell phones, vehicles, microwaves, computers, televisions — the list goes on. When there are shortages due to a lack of materials or slow production, that delay is felt up the supply chain by every consumer who is buying a new phone or computer, or even renting a vehicle.

Safe and efficient manufacturing of semiconductors is essential for life to continue unchanged. To keep customers happy and companies profitable, the manufacturing of semiconductors needs to happen in an environment where contamination can be strictly controlled, reducing the risk of product failures and losses.

The solution? Semiconductor cleanrooms. To illustrate why this piece of equipment is so valuable to the semiconductor industry, let’s first understand the purpose of cleanrooms and how that can help safeguard sensitive applications.

What is a Cleanroom?

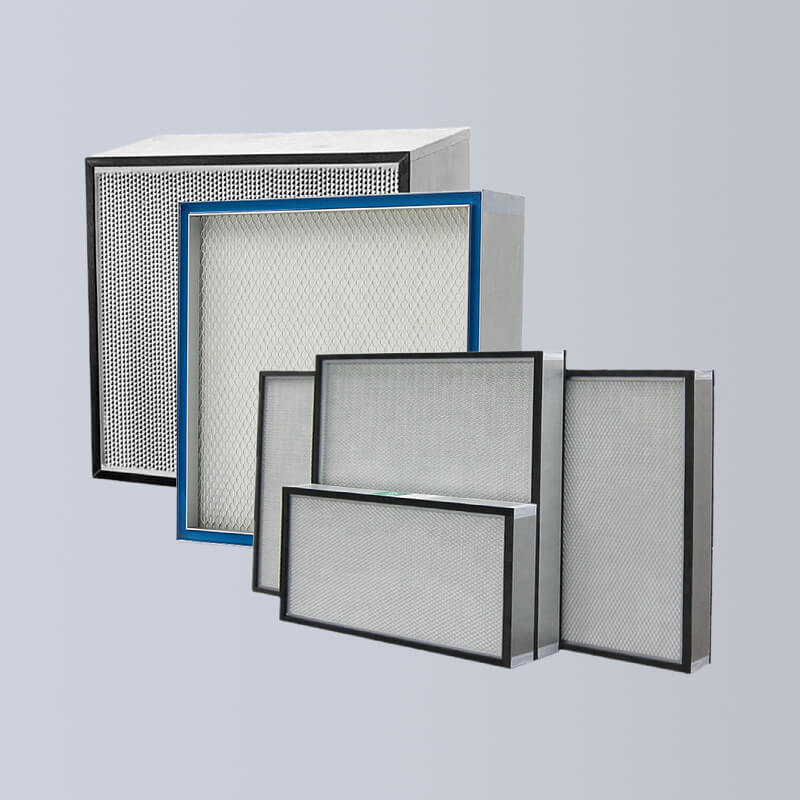

A cleanroom is a controlled environment where pollutants like dust, airborne microbes, and aerosol particles are filtered out in order to provide the cleanest area possible.

For manufactured products that are easily affected by contaminants or airborne particles, like semiconductors for example, a cleanroom can provide the necessary control over environmental factors like air quality, temperature, humidity, static electricity, and more.

Cleanroom classifications, designated by the International Standards Organization (ISO), define the minimal level of cleanliness required for cleanrooms in document 14644-1.

For semiconductor cleanrooms, the required control over environmental conditions is especially strict: Generally, semiconductor applications, including wafer fab and semiconductor assembly, require cleanrooms to comply with ISO Class 3 or cleaner standards.

The Value of Semiconductor Cleanrooms

For better results in semiconductor manufacturing and assembly, cleanrooms can provide the best environment for productive, efficient, and safe work to take place. Here are a few of the advantages cleanrooms can offer semiconductor applications:

Reliable Control

Cleanrooms are designed to establish strict control over the environment and maintain that control at all times. With powerful filtration and HVAC systems working to replace the air with clean, treated, and virtually particle-free air, you can trust the environment to remain stable while employees are completing their sensitive work.

All materials used in cleanroom construction are specifically sourced to be non-particle shedding and non outgassing. They’re chosen for durability and performance in any conditions. They won’t degrade or corrode due to cleaning, impact, or regular use.

Consistent Product Quality

Silicon wafers are extremely vulnerable, where even a single particle of dust can corrupt an entire chip or device. When you can rely on steady temperature, relative humidity, and air quality levels, product quality can also remain steady, even increase.

Repeatable Results

Better quality products and increased production in a controlled environment is a repeatable process. Scaling production is a matter of replicating the conditions required to produce excellent quality semiconductors.

Safer Working Conditions

A cleanroom and its classification standards protect the products being manufactured from failure due to contamination, but they also create a safer environment for workers to perform tasks in semiconductor cleanrooms, which can involve handling toxic materials and highly sensitive processes.

Cost Savings

Ultimately, fewer product failures and consistent quality pays off. With the risk of losses and injury reduced, your company can enjoy significant savings.

Semiconductor cleanrooms are not cheap to implement and operate, but they can secure profitability in ways you can’t replicate with other control methods. A high-quality cleanroom can streamline semiconductor manufacturing.

To learn more about semiconductor cleanrooms and get help designing your own, contact the cleanroom experts at Fete Filter Technology. We design, build, and install cleanrooms for a wide variety of industries to meet any classification standard. Our cleanrooms are the turnkey solution you’ve been looking for. Get a free quote for your project today.